PENTENS T-200H is based on a newly developed Water based Polyurethane and Acrylic Polymers. It is dramatically reduces solar heat absorption in either air-conditioned or non-air conditioned buildings. It takes the majority of the heat load off a building’s skin and reduces temperatures to approximately that of outside shade.

ADVANTAGES

- Water based, environment friendly

- UV protection

- Chemical resistant and waterproof

- Good adhesion

- Has a high rate of water vapor transmission

- High elongation

- Non-toxic

USES

PENTENS T-200H, which is one-part elastomeric cross linking PU latex copolymer emulsion designed as exposed waterproofing coating on:

- RC gutters and planter boxes

- Floor slabs

- Deck

- Wood siding/Fences

- External wall

- Flat roof

- Metal roof

- Concrete structures

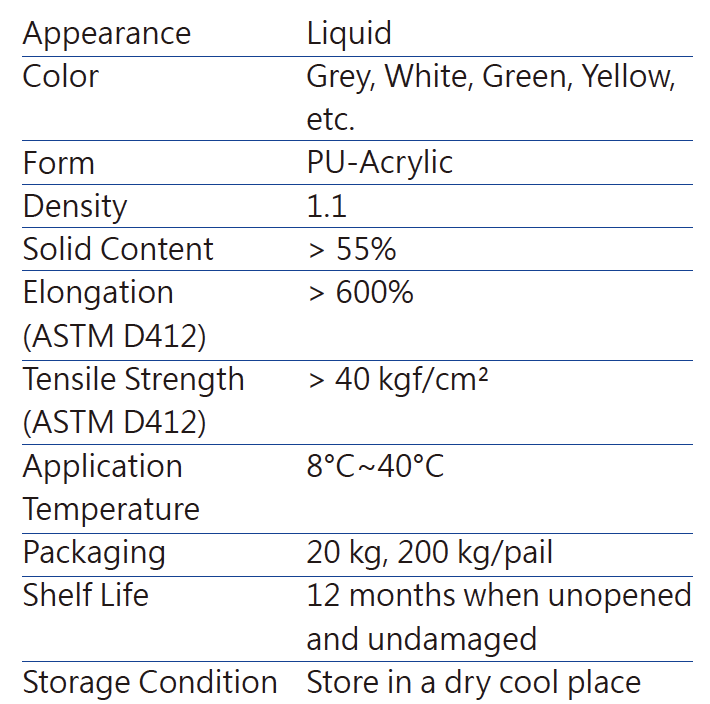

PHYSICAL DATA

APPLICATION

Surface Preparation

Surface must be sound, dry and clean (free of dirt, gravel, pollution, mildew and all foreign material). Apply if any rain is imminent. Repair flashings and damaged areas. Cracks and old bitumen joints shall be repaired first.

Application

Substrate should be primed with a 1:3 mixture of PENTENS T-007 and water. Brush on at the approximate rate of 0.3 kg/m². On areas exposed hot drying winds, 2 to 3 thin coats of paint may be more successful than 1 thick coat.

PENTENS T-200H is suggested to apply at least 2 coats. The first coat should be applied in one direction only. If possible the second coat should be applied at right angles to the first. (Called cross application method)

Leave to cure for approximately 8 hours before applying second coat. PENTENS T-200H can be installed with conventional airless spray equipment, brush or roller.

SAFETY

Impervious gloves and barrier cream should be used when handling these products.

Eye protection should be worn. In case of contact with eyes, wash thoroughly with plenty of water and seek medical advice if symptoms persist.

If contact with skin occurs, it must be removed before curing takes place.

Wash off with an industrial skin clearer followed by plenty of soap and water. Do not use solvent.

Ensure adequate ventilation when using these products.