PENTENS T-802 Waterplug

PENTENS T-802 A blend of hydraulic cements, wellgraded sands and chemical additives supplied in dry powder form to seal concrete, and masonry as a rapid setting remedy to plug active water instantly.

ADVANTAGES

- Chloride-free-does not promote corrosion of the reinforcement

- Ultra-rapid set-instant plugging of leaks

- Easy and safe to use-requires the addition of clean water only

- Expands as it sets-ensures a permanent watertight seal

- Good adhesion

- Excellent water-stopping power and hydraulic resistance

- Similar characteristics and compatible with concrete-durability to equal that of the structure

- Non-toxic after hardening

USES

- A seal for construction joints or floor joints prior to basement tanking with PENTENS Waterproofing System

- For instant sewer connections

- For sealing cracks and construction joints in reservoirs and other water-retaining structures

- For rapid anchoring of bolts, conduits, pipes, railings, sanitary equipment, etc

- Joint filling, pointing between concrete segments in concrete and brick tunnels, sewage systems, pipes and mines

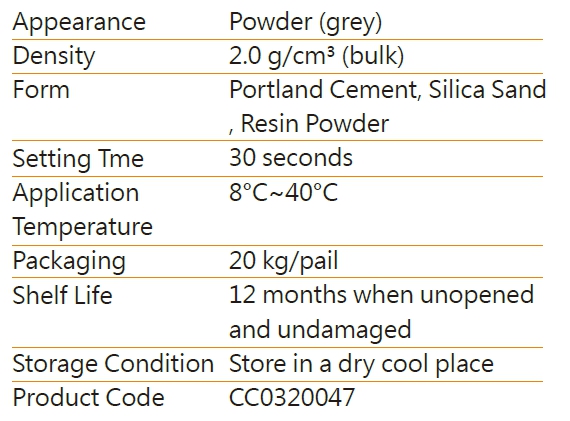

PHYSICAL DATA

APPLICATION

Surface Preparation

Cracks or holes should be cut out to a minimum width and depth of 20 mm; the sides should be cut as square as practicable. Undercut if possible. Avoid leaving a V-section. Do not feather-edge. Flush out the hole or crack with water at high pressure to remove all loose particles and dust.particles and dust.

Mixing

PENTENS T-802 Waterplug powder should be mixed with clean water by hand only.

Dampen all surfaces with clean water immediately prior to the application of T-802 Waterplug.

Application

Mix only sufficient material (0.5 kg) that can be placed by hand in one application. Mixed T-802 in the rubber gloved hand until slight setting occurs. Immediately press T-802 Waterplug mortar firmly into the opening; exert full pressure, without moving the hand until it sets.

Hold in place for approximately 60 seconds.

If the opening is too big to be closed, work progressively from the sides to the middle, following the above procedure.

SAFETY

Impervious gloves and barrier cream should be used when handling these products.

Eye protection should be worn. In case of contact with eyes, wash thoroughly with plenty of water and seek medical advice if symptoms persist.

If contact with skin occurs, it must be removed before curing takes place.

Wash off with an industrial skin clearer followed by plenty of soap and water. Do not use solvent.

Ensure adequate ventilation when using these products.