PENTENS EB-60J Epoxy Bonding Adhesive Anchor

PENTENS EB-60J is a solvent-free, 2-component thixotropic bonding mortar based on a combination of epoxy and selected quartz aggregates.

ADVANTAGES

- Can be applied to damp concrete surfaces

- Solvent free

- Rapid curing

- High compressive strength

- High mechanical strength

- High abrasion aresistance

- Shrinkage-free curing

- Easy to apply

USES

As an adhesive for bonding reinforcement, adhesive mortar to:

- Concrete, stone, steel, epoxy

For structural bonding of:

- Steel plates to concrete, concrete elements, bridge segments

For anchoring of:

- Starter bars, wall anchors

For vertical and overhead filling of:

- Holes, dimensional inaccuracies, etc.

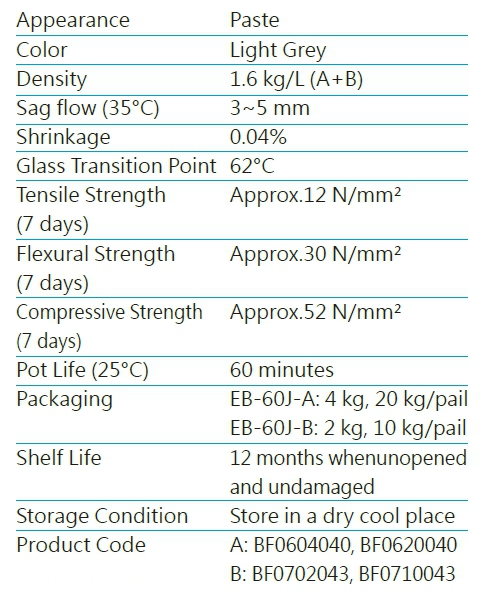

PHYSICAL DATA

APPLICATION

Surface Preparation

All the surfaces must be clean, free from grease, oil, laitance, and remove all the dirt and contaminants, which might affect adhesion.

Mixing

Mix com.A and com.B with an electric hand mixer at low speed (maximum 500 rpm) as little air as possible is entrained. The greater the quantity mixed, the shorter the pot life. To obtain longer workability at high temperatures, the mixed adhesive may be divided into portions.

Mixing ratio: A:B=2:1 (parts by weight).

Application

The well-mixed PENTENS EB-60J is applied with a spatula to the properly prepared substrate or PENTENS E-500 Low Pressure Epoxy Crack Injection System to a thickness of between 0.5 to 2mm. The adhesive must be applied with great care to the concrete surface to ensure that all voids are filled and no cavities are left.

Reinforcements must be positioned within the open time of the adhesive.

NOTE: When used as adhesive for PENTENS E-500, please refer to their respective product data sheets for details.

SAFETY

Impervious gloves and barrier cream should be used when handling these products.

Eye protection should be worn. In case of contact with eyes, wash thoroughly with plenty of water and seek medical advice if symptoms persist.

If contact with skin occurs, it must be removed before curing takes place.

Wash off with an industrial skin clearer followed by plenty of soap and water. Do not use solvent.

Ensure adequate ventilation when using these products.